Reverse Polarity (RP) SMA connector is most commonly used in various application among various RF connectors. Reverse Polarity (RP) SMA connector is designed to have thread coupling. Besides, Reverse Polarity (RP) SMA connector series are available for RF cables, PCB type and SMT type.

Wellshow Technology manufactures various Reverse Polarity (RP) SMA connectors and custom Reverse Polarity (RP) SMA RF cable assemblies in Taiwan. We can provide good quality in short time and welcome OEM or customized RF connectors. Contact us by email or call us 886-2-24270488 to start business!

RP SMA Connector Series

All RP SMA Connector | |

RP SMA Plug Connector | RP SMA Jack Connector

|

Information

The Reverse Polarity (RP) SMA Connectors are non-standardized versions of SMA connectors. Applications for reverse polarity connectors are based on the regulations of FCC for the limited purpose of connecting between Wireless LAN devices.

Reverse Polarity SMA connector and standard SMA connector have high quality and characterized by high durability, high mechanical stability, long service life and optimum electrical features.

Product Range

- Cable Connectors (straight and right angle) for flexible, semi-flex and semi-rigid cables

- PCB connectors (straight and right angle)

- Panel connectors in various flanges

- Adaptors

Application

- Cable Assembly

- Antenna

- Microwave Comonents

- Aero

- Instrumentation

- W-LAN

- Vehicle Tracking System

- GPS

- Telecommunications

- Cellular Mobile System

Specification

RP-SMA Connector Technical Characteristics

| Electrical | |

| Impedance | 50 ohm |

| Frequency range | 0 ~ 18 GHz |

| VSWR | Straight type ≤ 1.3 max. |

| R/A type ≤ 1.5 max. | |

| Dielectric withstanding voltage | 1000 V rms min. for RG142, RG405 750 V rms min. for RG316, RG402 500 V rms min. for RG178 |

| Working voltage | 500 V rms max. for RG142, RG405 375 V rms max. for RG316, RG402 170 V rms max. for RG178 |

| Center contact resistance | ≤ 6.0 mΩ (Milliohms max.) |

| Outer contact resistance | ≤ 2.0 mΩ (Milliohms max.) |

| Insulation resistance | ≥ 5×103 MΩ (Megohms min.) |

| Mechanical | |

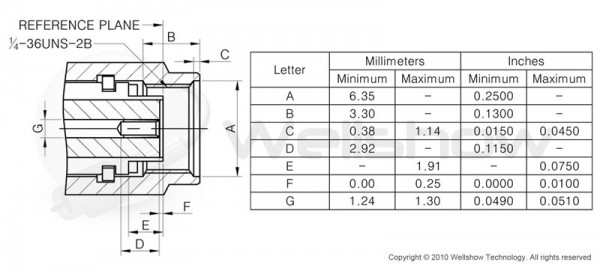

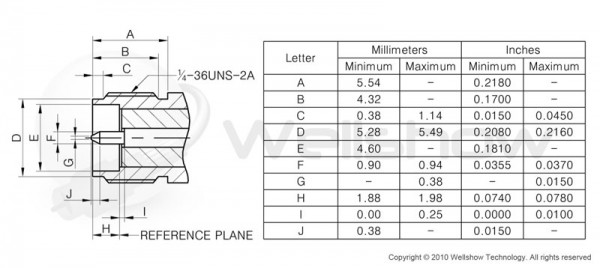

| Coupling | 1/4-36 thread |

| Contact Retention | 15 in-lbs. min. |

| Mating torque | 2 in-lbs. min. |

| Mating Durability | 500 cycles min. (For Beryllium copper contact only) |

| Environmental | |

| Temperature Range | −65ºC ~ +155 ºC |

| Vibration | MIL-STD-202 Meth. 204 |

| Corrosion resistance | MIL-STD-202 Meth. 101 |

| Materials | |

| Body, coupling nut | Brass, Non-magnetic stainless steel |

| Insulator | Teflon |

| Center contact | Brass for male, Beryllium copper for female |

| Crimping sleeve | Annealed Brass |

| Body plating | Nickel (Ni), Gold (Au), Passivated |

| Center contact plating | Gold (Au) |